-

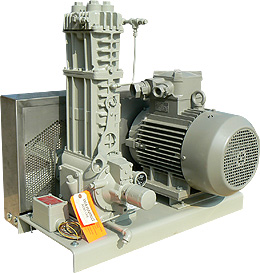

CORKEN VERTICAL LPG COMPRESSORS

The CORKEN liquid transfer-vapor recovery compressor is a vertical single-stage, single-acting reciprocating compressor designed to handle flammable gases like LPG and toxic gases such as ammonia. Vertical compressors are also perfect for emergency evacuation purposes. Compressors are available in both threaded and ANSI flanged connections.Stationary and trucks applications

Usually CORKEN vertical compressors are used in stationary applications in terminals, for railcars unloading and trucks loading/unloading. Compressors have also an extended crankshaft option for utilization on trucks for loading/ unloading as well as vapor recovery, with PTO and hydraulic drive systems.

We can supply bare or mounted compressors with Siemens ex proof motors AOM, ExdIIB+H2T4Gb.

Specifications

Model 91 291 491 691 D891 Inlet ¾“ ¾“ 1¼“ 2″ 2″ weld Outlet ¾“ ¾“ 1¼“ 1½“ 2″ weld Bore of cylinder mm 76,2 mm 76,2 mm 101,6 mm 114,3 mm 113 mm Stroke mm 63,5 mm 63,5 mm 76,2 mm 101,6 mm 101,6 mm Piston displacement m3/hr

Minimum at 400 RPM

Maximum at 825 RPM6,8 m3/hr

14,1 m3/hr13,6 m3/hr

28 m3/hr29,2 m3/hr

60,3 m3/hr49,6 m3/hr

102,3 m3/hr96,2 m3/hr

192 m3/hrMax. Working pressure 23,1 bar 32,1 bar Max. brake kW 5,6 kW 11 kW 11 kW 26,1 kW 34 kW some text goes here… Max. rod load kg 1632,9 kg 1632,9 kg 1814,4 kg 3175,1 kg 3175,2 kg Max. outlet temperature °C 177 °C Max. Flow – propane m3/hr 11,4 m3/hr 22,9 m3/hr 48,8 m3/hr 82 m3/hr 157,6 m3/hr ANSI/DIN flange option

Inlet/outletF91

¾“ANSIF291

¾“ANSIF491

1¼“ ANSIF691

2″ ANSI– Standard specifications and material

- Ductile iron construction

- 91: splash lubricated crankcase; 291-891: pressure lubricated crankcase

- Liquid relief suction valves

- Self-lubricating PTFE piston rings

- Aluminum gasket material

- Buna-N O-ring

- Standard flywheel

- Nitrotec piston rod coating

Mountings

- Basic mounting: 103 type, incl. steel baseplate, V-belt drive, adjustable driver slide base, steel belt guard, suction and discharge pressure gauges mounted on the compressor

- For LTVR (liquid transfer vapor recovery) operations: 107 type, incl. all 103 items plus 40micron strainer, non-lube 4-way valve, interconnecting piping, liquid trap

- 107: mechanical liquid trap with ball float

- 107A: with automatic liquid trap with one NEMA 7 liquid level switch to stop compressor

- 107B: with ASME code liquid trap with two NEMA 7 liquid switches for alarm and stop compressor

- For operations, where vapor recovery is not needed: 109 type, incl. all 103 items plus interconnecting piping, liquid trap

- 109: mechanical liquid trap with ball float

- 109A: with automatic liquid trap with one NEMA 7 liquid level switch to stop compressor

- 109B: with ASME code liquid trap with two NEMA 7 liquid switches for alarm and stop compressor